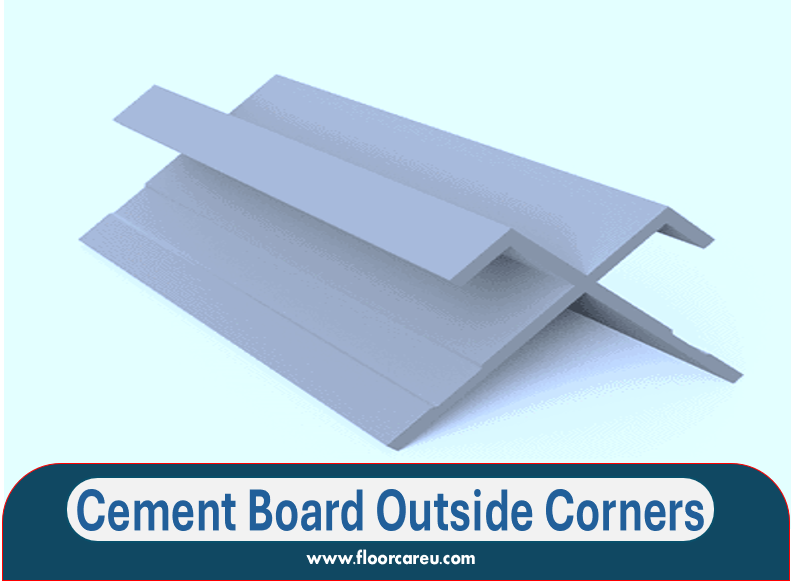

Cement Board Outside Corners: Cement board outside corners are typically finished using metal corner beads for added protection and a clean look. These corner beads ensure the edges of the cement board are safeguarded and provide a smooth transition to other materials like drywall.

Concerning exterior applications, cement board is a durable and moisture-resistant solution that offers enhanced longevity and mold prevention. Installing cement board provides a reliable barrier against moisture, making it ideal for outdoor use. Additionally, using corner beads ensures a secure and professional finish when transitioning between cement board and other wall materials.

Understanding the proper techniques for handling cement boards outside corners is essential for achieving high-quality and long-lasting results in construction and renovation projects. By carefully following industry best practices and using the appropriate materials, such as metal corner beads, individuals can effectively address exterior corner transitions, ensuring functional and aesthetic success.

Benefits Of Cement Board

Cement board outside corners provides numerous benefits for exterior walls. They are durable, easy to install, and help prevent water damage by keeping moisture out of buildings. Additionally, cement board exterior walls are resistant to mold and mildew.

Cement board is a popular building material known for its strength and resilience. It offers several benefits that make it a preferred choice for construction projects. Let’s delve into some of the key advantages of using cement boards.

Enhanced Durability

The cement board is renowned for its exceptional durability, making it an ideal choice for outside corners. It can withstand harsh weather conditions, ensuring long-lasting stability for exterior applications.

Moisture Resistance

One significant benefit of cement board is its excellent moisture resistance. It effectively repels water, preventing moisture-related issues such as mold and mildew, common in exterior environments.

Prevention Of Water Damage

A cement board provides a robust barrier against water infiltration, safeguarding the structure from potential water damage. Its moisture-resistant properties make it a reliable solution for maintaining the integrity of exterior surfaces. Overall, the use of cement board presents a compelling case for enhancing durability, moisture resistance, and water damage prevention for outside corners, making it a valuable investment for construction projects.

Installation Process

First, apply thin-set adhesive to the corner area to install cement board outside corners. Next, embed alkali-resistant mesh tape, ensuring a smooth finish. Finally, apply a coat of thin-set mortar over the tape and feather the edges for a seamless transition.

This process provides durability and moisture protection for exterior walls.

The installation process of cement board outside corners is crucial to ensure a durable and long-lasting finish. Proper techniques and materials are essential to transition from cement board to drywall seamlessly. This section will discuss the required tools and materials, provide a step-by-step guide to installing cement boards, and share tips for a successful installation.

Tools And Materials Required

To install cement board outside corners, you will need the following tools and materials:

| Tools | Materials |

|---|---|

|

|

Step-by-step Guide To Installing Cement Board

Follow these steps to install cement board outside corners:

- Measure the length of the corner where the cement board will be installed.

- Mark the cement board to the desired length and cut it using a utility knife and a straight edge.

- Apply a layer of thin-set mortar to the corner using a trowel or putty knife.

- Press the cement board onto the thin-set mortar, ensuring it is firmly adhered to the corner.

- Secure the cement board in place with nails or screws, making sure they are evenly spaced.

- Apply a layer of alkali-resistant mesh tape to the seams of the cement board.

- Cover the mesh tape with a layer of all-purpose joint compound, smoothing it out with a trowel or putty knife.

- Allow the joint compound to dry completely, then apply additional coats if necessary, sanding between each coat for a smooth finish.

- Once the joint compound is dry and smooth, prime the cement board and apply the desired paint or finish.

Tips For A Successful Installation

Here are some tips to ensure a successful installation of cement board outside corners:

- Always wear protective gear, such as gloves and a mask, when working with cement board and joint compound.

- Ensure the cement board is cut to the correct length and fits tightly against the corner.

- Use the appropriate screws or nails for securing the cement board, making sure they are installed at the recommended distance from the edges.

- Apply thin-set mortar evenly to ensure proper adhesion of the cement board.

- Smooth out the joint compound to achieve a seamless finish, using multiple coats if necessary.

- Allow sufficient drying time between coats of joint compound before applying primer and paint.

By following these guidelines and using the right tools and techniques, you can confidently install cement board outside corners to create a durable and visually appealing finish for your project.

Transitioning To Drywall

Transitioning to drywall with cement board outside corners involves careful taping and joint compound application to blend the two materials seamlessly. Feather the corner bead and use cement board tape for a professional touch. Upgrade exterior walls with durable cement board for enhanced moisture resistance.

When installing cement boards outside corners, one important aspect to consider is the transition to drywall. This transition requires careful attention to ensure a seamless and professional finish. This section will explore methods and techniques for smoothly transitioning from cement board to drywall.

Ensuring Seamless Transition

Proper taping and finishing techniques are essential for a seamless transition between cement board and drywall. By following these techniques, you can achieve a professional result that blends the two materials seamlessly.

Taping And Finishing Techniques

- Apply Joint Tape: The first step in taping and finishing the transition is to apply joint tape. Cut the tape to the desired length, ensuring it extends beyond the corner. Using a drywall knife, apply a thin layer of joint compound to the corner, then press the tape into the compound, smoothing out any wrinkles or bubbles.

- Feathering the Compound: Feathering the joint compound is important to create a smooth transition after applying the tape. Applying a compound layer to both sides of the corner using a wider drywall knife, gradually tapering the compound towards the middle of the transition. Repeat this process until the transition feels smooth to the touch.

- Sanding: Once the compound is dry, sand the transition area with fine-grit sandpaper to smooth the surface further. Wear a dust mask while sanding to protect yourself from dust particles.

- Apply Additional Layers: Depending on the desired finish, you may need to apply additional layers of joint compound to achieve a seamless transition. Apply each layer with a wider drywall knife than the previous layer, gradually feathering the compound to blend it with the surrounding drywall.

- Prime and Paint: Finally, prime and paint the transition area to enhance its seamless appearance further. Use a high-quality primer and paint that matches the color of the surrounding drywall. These taping and finishing techniques ensure a seamless transition from cement board to drywall. This enhances the aesthetic appeal and provides a durable and long-lasting finish.

Exterior Applications

For durable exterior applications, consider using a cement board on outside corners to transition between surfaces seamlessly. PermaBASE Cement Boards enhance durability and moisture resistance for external walls, preventing common water damage issues like mold and mildew. Lightweight and easy to install, they offer long-lasting protection.

Suitability For Outdoor Use

PermaBASE cement board products are designed for exterior applications, making them an ideal solution for outdoor projects. The boards are specifically engineered to withstand prolonged exposure to the elements and are well-suited for use in outdoor settings.

Advantages Of Permabase Cement Boards

When used in exterior applications, PermaBASE cement boards offer several advantages:

- Enhanced Durability

- Moisture Resistance

- Prevention of Mold and Mildew

PermaBASE cement board exterior walls better keep moisture out of buildings, helping to prevent common forms of water damage. These boards are also lightweight and easy to install, providing a durable exterior sheathing that can withstand the challenges of outdoor environments.

Special Considerations For Corners

Dealing With Outside Corners

Paying attention to the corners, especially outside ones, is crucial when installing cement boards. These areas require special considerations to ensure a professional and durable finish.

Use Of Corner Beads For Cement Board

Using corner beads is essential to handling outside corners with cement board. These beads provide structural integrity and a clean edge, preventing damage and ensuring longevity.

Expert Advice And Recommendations

Insights From Professionals

Professionals suggest using cement board for outside corners due to its durability and moisture-resistant properties.

Best Practices For Finishing Corners

- Apply cement board tape meticulously to ensure proper adhesion and prevent corner cracks.

- Use a high-quality joint compound to achieve a smooth finish at the transition between cement board and drywall.

- Inspect walls for squareness before applying any finishing materials to maintain a symmetrical appearance.

- Consider waterproofing membranes for added protection against moisture infiltration in exterior applications.

Experts highlight the importance of proper tools and materials for a successful corner finishing process, including cement board tape, joint compound, and waterproofing solutions.

Frequently Asked Questions Of Cement Board Outside Corners

Do I Need To Tape the Corners Of the Cement Board?

Yes, it is necessary to tape the corners of the cement board to ensure proper reinforcement. Taping helps to prevent cracking and provides a smooth surface for finishing.

How Do You Finish A Corner Where Cement Board Meets Drywall?

To finish a corner where the cement board meets drywall, combine cement board tape and joint compound. Apply the tape over the joint, then spread a thin coat of joint compound over it. Feather the edges and let it dry before applying additional coats if needed.

Will the Cement Board Hold Up Outside?

Yes, the cement board can hold up outside. It is easy to install, durable, and helps prevent moisture damage and mold. PermaBASE cement board products are ideal for exterior walls and provide enhanced durability. They are lightweight and made with Portland cement, aggregate, and fiberglass mesh.

Can I Use Cement Board Externally?

The cement board can be used externally as it is durable and provides enhanced protection against moisture, mold, and mildew. PermaBASE Cement Boards are lightweight, easy to install, and ideal for exterior applications.

What Is The Purpose Of Cement Board Outside Corners?

A: Cement board outside corners provide a smooth transition and added strength to the corners of exterior walls.

How Do You Finish The Joint Between Cement Board And Drywall?

A: To finish the joint between the cement board and drywall, apply joint compound and tape, ensuring a seamless and secure connection.

Conclusion

Cement board outside corners enhance exterior walls’ durability and moisture resistance. Utilizing durable products, such as PermaBASE Cement Boards, ensures prolonged exposure to moisture without compromising quality. With proper installation techniques and corner beads, these solutions provide a lasting and reliable exterior finish for buildings, effectively preventing water damage and mold formation.